Wire & Sinker EDM

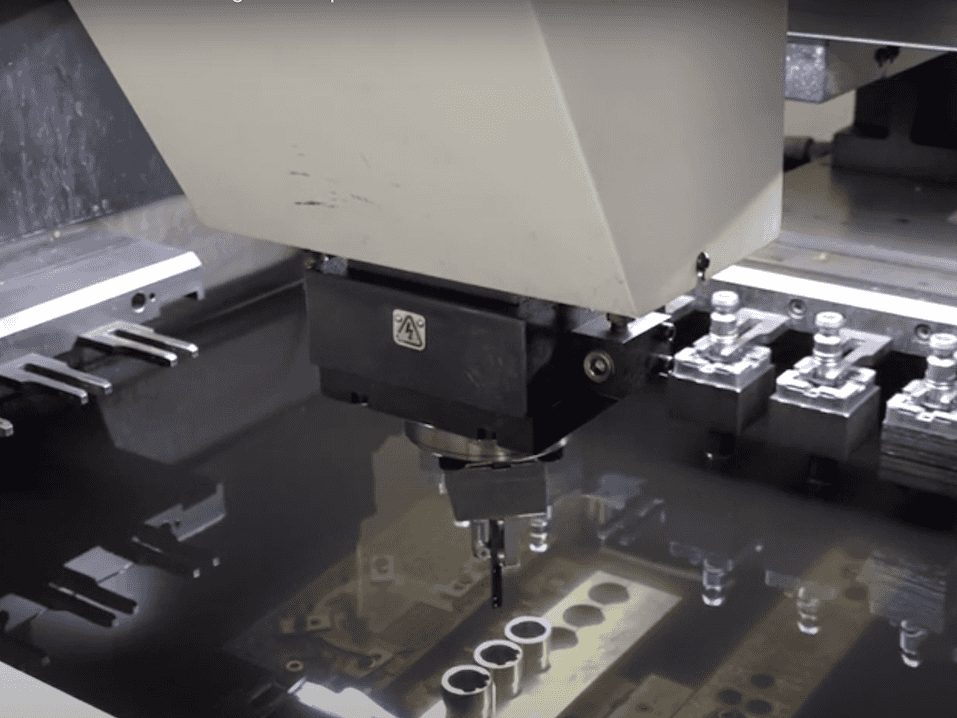

Electrical discharge machining (EDM) creates desired shapes in metal components by removing material using an electrical discharge or sparks. The process occurs with the workpiece submerged in deionized liquid and employs an electrode cutting material.

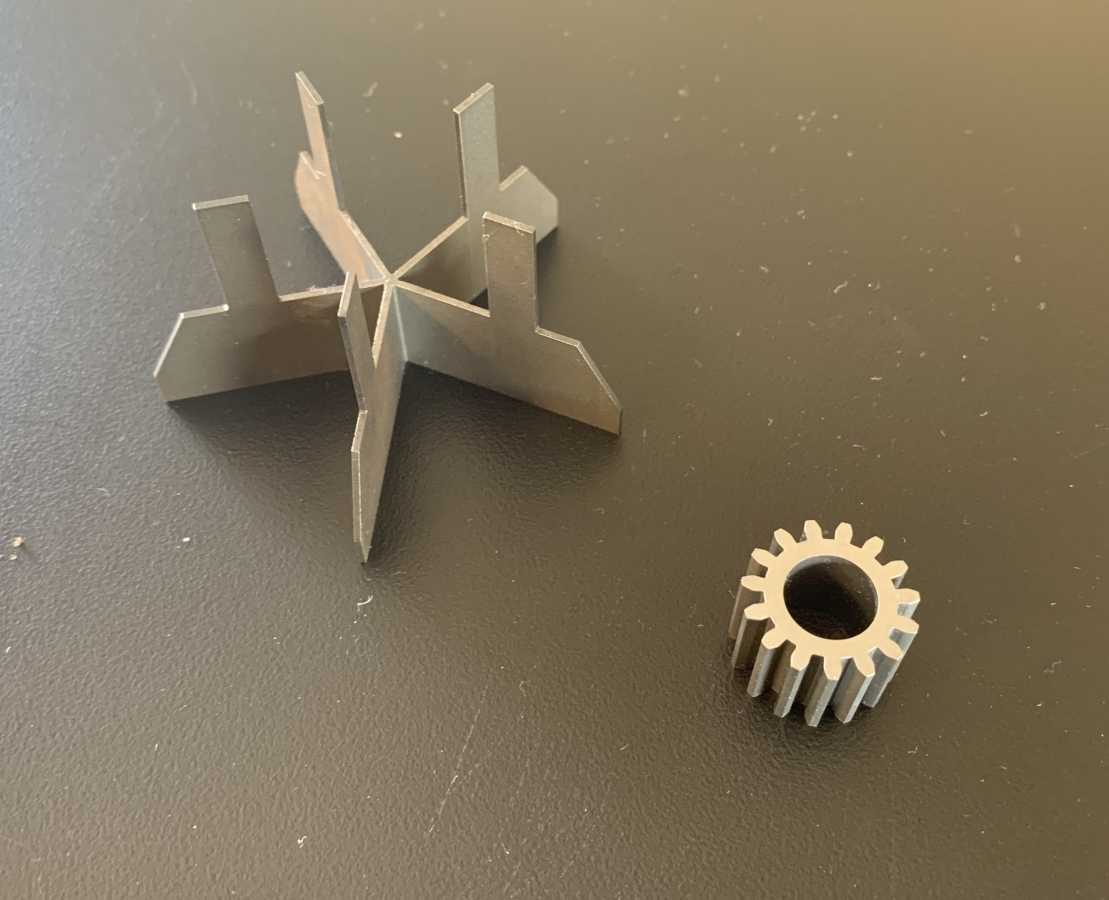

EDM processes can create intricate contours and cavities not possible with any other machining process. Electrical discharge machining can also create extremely complicated part geometries with tight tolerances. EDMing is well suited for cutting exceptionally hard metals such as tungsten and titanium. It is often used as a last resort process when simply no other technology exists to satisfy design requirements.

Compass Precision offers both wire and sinker EDM processes. We have five wire and two sinker Agie machines at Advanced Machining. In addition, we have a Sodick wire EDM unit at Douglas Machining.

As with our other equipment selection strategies, having most of our EDM machines from the same vendor makes it easier to train personnel, perform maintenance, and maintain production even when faced with unscheduled equipment downtime.