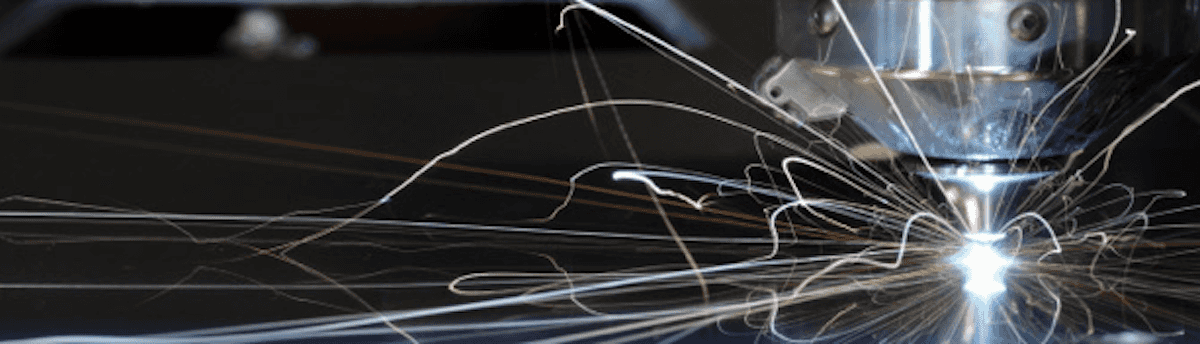

Laser Cutting

Laser cutting of sheet metal has largely displaced water jet cutting and other older technologies for creating individual parts from metal sheets. The most modern laser cutting machines are high power units capable of fast cutting through thicker materials and are equipped with automated loader/unloaders to provide unattended, lights-out production alternatives.

Lasers are extremely accurate for cutting sheet metal. They are nearly as fast, sometimes faster, than traditional fabricating processes like shearing and punching, particularly with thin materials. Laser cutting does not require dedicated, expensive tooling. Even special shapes can be programmed quickly, with virtually no setup time required.

Compass Precision has two CNC laser cutters. One is a 2500-watt Amada unit. It has a robotic loader/unloader that was added in August 2020. We also have a Mazak 1500-watt laser cutter.