Shops That Utilize Everyone’s Talents Win Championships

Compass doesn’t behave like most companies, with bosses barking orders and underlings scurrying to comply. To better understand why, we queried Compass CEO Gary Holcomb and recorded his comments below

What’s the deal with how Compass makes management decisions?

Compass Precision prides itself with decentralized management, putting decision making in the hands of those closest to the action and customer. This means managers running each of our seven operating companies are encouraged to behave as true entrepreneurs, as if they owned the shop. In turn, each individual working for these managers is tasked to contribute with his/her intelligence, not just manual labor. Hard working employees are great, but hard working and smart thinking employees are better.

Why don’t all companies behave this way?

Some industries require massive scale to be successful. Semiconductor manufacturing, for example, requires $5-10 billion fab facilities and thousands of specialized employees. But CNC machining is different. You only need a handful of great machines and maybe a dozen people to be a really good custom shop. Firms this size can be extremely proficient at making certain classes of precision machined parts.

You have said Compass is a 140-person company that behaves like seven 20-person shops. What do you mean by this?

We believe strongly that the optimal size for a precision CNC machining company is 10-40 employees. Assuming it has the right equipment, such a shop is big enough to totally satisfy customer needs for a particular family of parts, yet flexible enough to adjust quickly to customer needs.

Are there examples of this in other industries?

Yes, take the casual dining industry for example. No meaningful economies of scale other than advertising exist. Assuming a smart consumer has already identified restaurants in his area (negating the value of advertising), many astute buyers gravitate towards individually owned eateries due to their greater selection of offerings and ability to customize meals. For about the same price, you get more choices and better service. I believe the same is true of small-to-mid size CNC shops versus their much bigger competitors. Having fifty 5-axis machines isn’t better than having five.

What about within an individual shop – isn’t it more efficient to have one or two people making all the decisions?

Yes, we have a bunch of extremely talented people running each of our operating companies. But one of the reasons each is successful is his or her ability to get everyone involved, to encourage and solicit input from all parts of the organization. Sports championships are won by teams, not individuals. Even Super Bowl MVP Patrick Mahomes needs people blocking for him and catching his passes. Our shops are no different. And in fact, they are successful precisely because everyone is contributing.

Ok, so Compass pushes decision making down to the lowest possible level in the organization and involves everyone in the shop. Why does this matter?

Utilizing our entire team makes us a better supplier. Here is an example. One of our top customers called us in a panic recently. The parts we just shipped them didn’t fit into their assembly. Our team went into overdrive to solve the problem. One employee investigated the problem with customer’s engineer and discovered the root cause. Second employee rushed over to customer’s location and picked up parts. Third employee reworked parts while first employee explained to customer that original drawings did not specify flatness tolerance required by rest of assembly. Second employee returned reworked parts to customer. All of this happened on a Tuesday morning before 11am.

Does everything within Compass happen within each operating company?

Great question, but the answer is no. We centralize things like accounting, finance, banking relationships, digital marketing, business development with new customers, HR, health insurance administration, and other support services. There are two reasons for this. First, it is usually more efficient. And second, offloading these tasks allows our people in each operating company to focus on making great parts and serving customers.

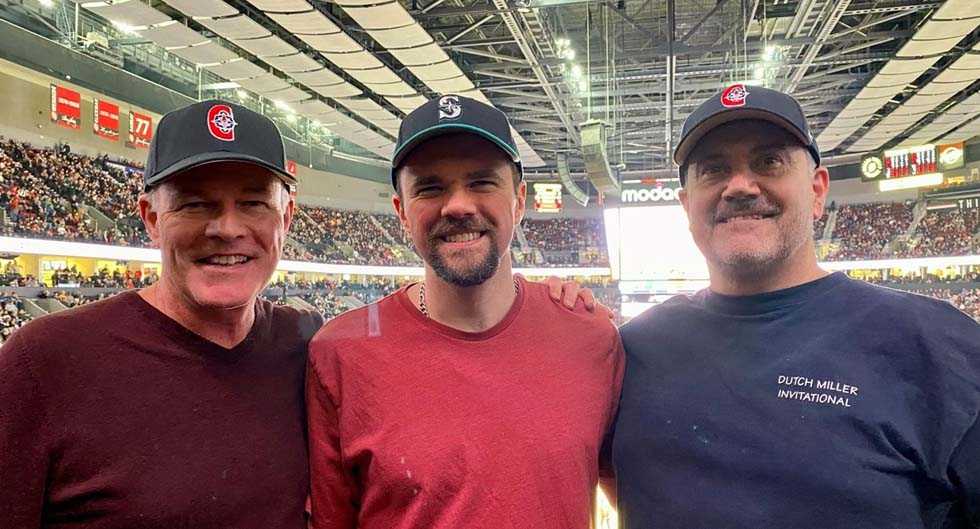

Finally, gotta ask. What’s the deal with this photo?

During my recent visit to Strom Manufacturing, our operating company near Portland, several of us saw the Portland Trailblazers play the Milwaukee Bucks The Bucks won handily despite Blazers’ star Damian Lillard outscoring his Bucks’ counterpart Giannis Antetokounmpo. If this doesn’t show the importance of team versus individual contributions, I don’t know what does.

For more information about Compass or its team orientation towards doing business, please contact CEO Gary Holcomb directly at [email protected].