Douglas Machining Reaches Company Milestone

Hard work always pays off. Dan Douglas is the living embodiment of this saying being true.

After working 15 years for machine shops around Winona, MN, Dan decided it was time to work for himself. So, he opened his own machine shop – Douglas Machining.

The Compass Precision operating company turns 20 years old in March 2025.

“It’s cool to take pride in seeing what started out 19 years ago when I started, 20 years ago for the company,” said current Douglas co-general manager Ben Kubis. “We began as two guys and two CNCs and grew to 15, 16 guys and 20-plus CNCs. It was pretty neat to see what came from it.”

“If you want things, you have to work for it. He’s a true, not rags to riches story, but we weren’t rich by any means growing up. But he’s obviously done well for himself, and that’s all because he worked really hard,” said current Douglas co-general manager and Dan’s daughter, Christina Douglas.

“Hard work always pays off, so I kept shooting for the stars,” Dan said while reflecting back on 20 years.

Douglas Machining employees heard Dan utter his “hard work always pays off” slogan constantly over the years. He liked using other slogans too such as the one that still hangs on a sign in the Douglas machining shop. The photo below is of this sign.

“Quality Machining Delivered On Time to Meet Our Customers Needs”

But when Douglas Machining first started, the only person Dan could say his slogans to were himself. He opened the machine shop with a two-axis lathe, a manual mill, a Brown & Sharpe screw machine, a saw and a forklift. The only worker was himself.

He kept his goals realistic.

“I was just trying not to go belly-up. It’s a big deal when you start a new business,” said Dan. “You don’t have another existing business to work for. It’s a do or die situation.

“You don’t have anyone to fall back on but yourself.”

In the first several months, Dan made a lot of cold calls to build his business from nothing. Looking back at it now, Dan said he needed customers to take a chance on him.

To earn their trust, Dan made his business about them.

“It’s always about customer service but even more so in the beginning. When you get that opportunity, you can’t blow it.”

Once trust was earned, Dan described that it “worked out for everybody.” And once Douglas Machining gained a customer, they were never lost.

While at another shop in Winona, Dan trained a young machinist named Ben Kubis. It just so happened that Dan and Ben crossed paths again just as Douglas Machining was preparing to hire its first employee.

About a year and a half after founding his business, Dan met Ben’s brother-in-law. Ben’s name was dropped in their conversation, which led to Dan hiring Ben as his first employee.

Douglas Machining was growing, but the company still needed extremely hard work to survive. On many occasions, Dan and Ben worked around the clock to fulfill customer requirements.

The company kept growing, which allowed Douglas Machining to add new machines. That also created more work for the company’s two-man team.

A third machinist joined Dan and Ben, giving them another set of hands to work 24/7. When necessary, Dan and Ben started working at 4 AM and ran machines until 4 pm, which is when the third employee took control of the shop for his own 12-hour shift until 4 AM.

“In those early years, it was tough for two of us to keep those machines running for 12-hour shifts,” said Ben. “We were responsible for 3-4 machines each.”

When the 2008 recession came, Dan had to cut the third person. But Ben has stayed with the company for 19 years.

Ben, along with the other Douglas employees Dan has hired over the years, have become like family. Dan also described that a lot of his customers have become “lifelong friends.”

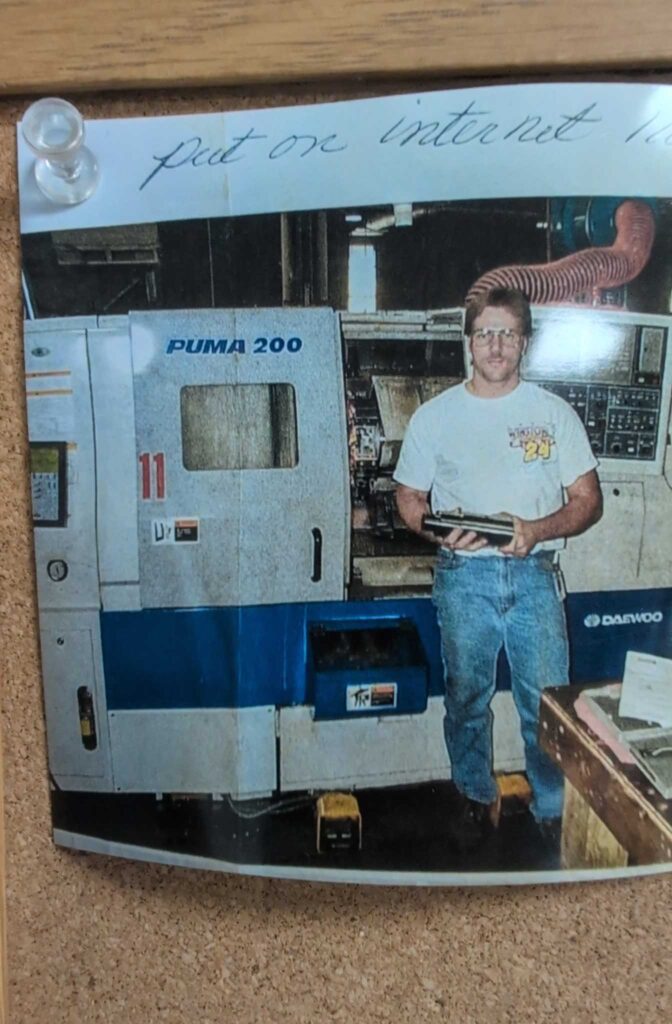

In many ways, Douglas Machining has always been a family affair. Dan’s mother designated herself as the company’s cleaning lady in the early years of the company. She sometimes helped place finished parts in boxes for shipping as well. The photo at right is one she took of Dan back in those early years.

In many ways, Douglas Machining has always been a family affair. Dan’s mother designated herself as the company’s cleaning lady in the early years of the company. She sometimes helped place finished parts in boxes for shipping as well. The photo at right is one she took of Dan back in those early years.

Christina described her grandmother as “very proud” of Dan. Other family members, both blood related and in-laws, offered Dan their support over the years.

Christina first helped her father’s business by running parts overnight when she was in high school. Her efforts kept the machines running and gave her a little extra spending money.

When she attended college, Christina thwarted Dan’s plan for her to become the company’s accountant. Instead, she found sociology courses more fulfilling.

But roughly a decade later, which included four years of Christina serving as a corrections officer for the state of Minnesota, Dan convinced Christina to move to Winona to become Douglas Machining’s office manager.

A couple years later, Dan’s son, Zak, began working at Douglas Machining as well. He swept floors and cut material in the machine shop as early as eight years old. At an even earlier age, he practiced driving the company’s forklift (see photo at right). Zak began working part time at Douglas immediately after high school and accepted a full-time role as a machinist with the company about a month later.

A couple years later, Dan’s son, Zak, began working at Douglas Machining as well. He swept floors and cut material in the machine shop as early as eight years old. At an even earlier age, he practiced driving the company’s forklift (see photo at right). Zak began working part time at Douglas immediately after high school and accepted a full-time role as a machinist with the company about a month later.

Whether it was with his children, Ben or the new employees Douglas has added over the last two decades, Dan stressed the same philosophy – hard work pays off.

Dan’s hard work continued to result in a growing business. After exhausting all expansion options, Douglas Machining moved into a bigger building in 2013. As the company added new machines, it began specializing in mill/turn to further improve satisfying customer needs.

“Everytime you touch a part, it costs you money. Human error that can happen, with those machines, it can’t happen. You program the machine to tell it what to do, and that’s what it does,” said Dan.

While Douglas celebrated its 16th anniversary in March 2021, Dan sold his company to Compass Precision. Douglas’ “set it and forget it” philosophy with its mill/turn units fit perfectly into the Compass brand.

For the past four years, Douglas Machining has been a sister company to several other CNC machine shops across the United States. Today, Douglas is one of eight sister companies with more coming at Compass.

As a Compass operating company, Douglas receives corporate support for its growth. But there have been minimal changes at the Douglas machine shop.

“Compass did what they said they were going to do. Compass came in, but they left it alone,” Dan said. “They let the people who had been running the business continue running it.

“That was one of the biggest factors for me to sell. I didn’t want somebody to come in, turn everything upside down and ruin it.”

Douglas Machining went through another transition in 2022 with Dan’s retirement. Christina and Ben assumed co-general manager roles at Douglas Machining.

But again, little has changed.

“We try to do everything we can to keep our customers happy and to try and keep growing,” Ben said. “Whatever it takes to get the parts done, keep the customers happy. We try to do the same thing we’ve always done.”

Dan’s presence can still be felt throughout the building. The signs with his famous slogans remain on the wall. Other things Dan enjoyed saying are on company t-shirts.

It’s important to Douglas employees that those aren’t just sayings but that the company continues to live by them on a daily basis.

“It’s a great way of living on the Douglas Machining legacy even after he’s stepped away. He prided himself on that slogan everyday too,” Zak said. “He didn’t want bad stuff going out and angry customers. So I think that’s a great way that we try to keep the legacy alive.”

“With my Dad leaving, I care about Douglas because I want my Dad’s legacy to live on,” Christina said. “He worked so hard to have this company, and I think it’s pretty special.”