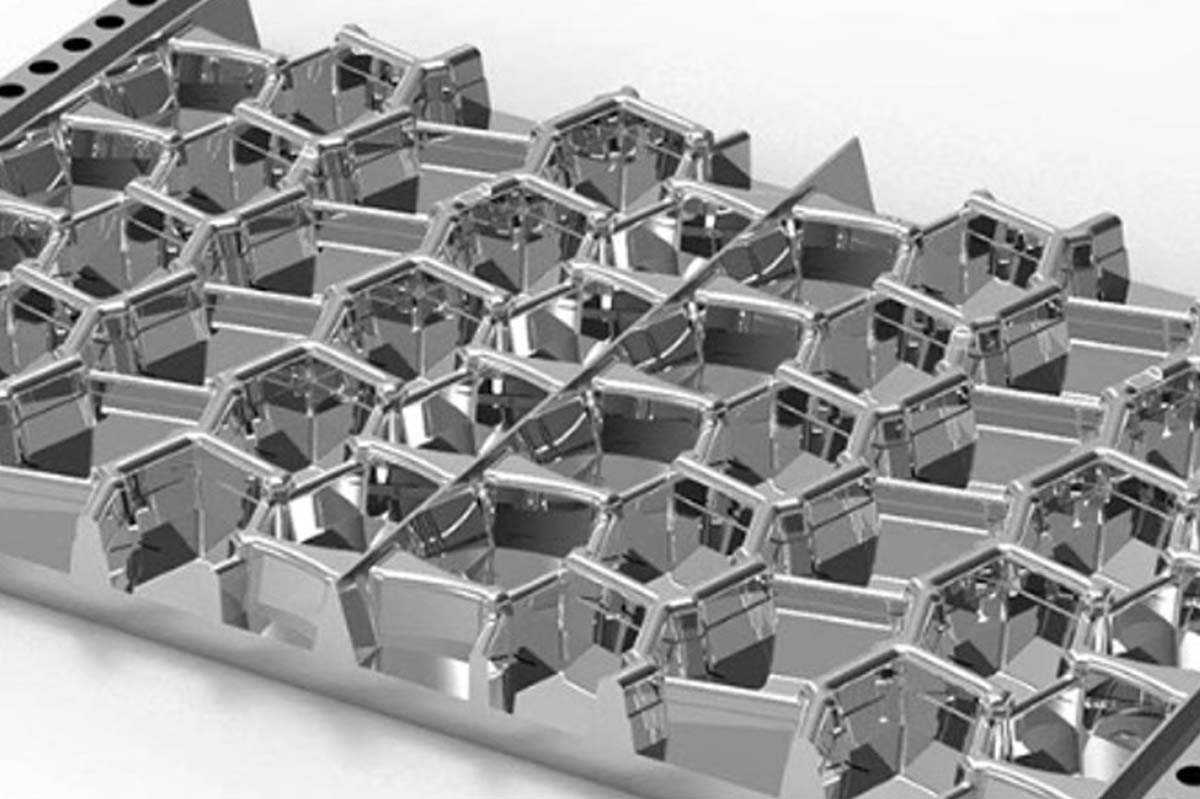

We make the tough stuff… CNC machined & fabricated parts with demanding geometries, tight tolerances, exacting surface finishes, and difficult-to-work-with materials.

If “chips” are involved, we do it.

- Headquartered in Charlotte, NC

- Eight facilities across the US

- Prototype, small, medium, and large volumes

- Full complement of machining processes

- Aggressive investment in PP&E

- Many facilities ISO/AS9100D/ITAR/CMMC certified

Equipment

- 22 five-axis vertical mills

- 56 three/four-axis vertical mills

- 6 four-axis horizontal mills

- 17 multi-tasking mill/turn machines

- 27 lathes

- 27 Swiss screw machines

- 8 EDM machines

- 13 CMM machines

Plus various laser cutters, press brakes, punch presses, welding stations, and related fabrication & assembly equipment

Our equipment is modern, advanced, and well maintained. We can machine nearly any geometric shape less than 30 inches in length and 6 inches in diameter. Our maximum envelope is 120 inches by 40 inches by 30 inches.

Materials

We routinely work with difficult-to-machine materials that most shops won’t quote.

- Titanium

- Inconel

- Monel

- Aluminum

- Copper

- Nickel-Based Alloys

- Stainless Steel

- Tool Steels

- Engineered Plastics

We proudly serve the most demanding industries. Mission critical parts are our forte.

- Aerospace

- Defense

- Industrial Automation

- Medical

- Power Generation

- Semiconductor

- Space

- Specialty Industrial & Consumer

- Telecommunications

We even have a component on Mars.

Our eight facilities comprise 155,000 square feet of great manufacturing space, including shops that are ISO 9001:2015, AS9100D, ITAR, CMMC, and AWS certified. We have the infrastructure, equipment, and expertise to be your best supplier of precision metal components… the more difficult the project, the better we are.